Robot Training Camps are large-scale simulated environments where embodied AI robots are trained through reinforcement learning before being deployed in the real world.

These environments reduce cost, risk, and development time by enabling large-scale sim-to-real transfer across factories, warehouses, and homes.

In late 2025, the artificial intelligence narrative has shifted dramatically. We have moved beyond chatbots that write poetry to Embodied AI: intelligent systems that possess a physical form and can interact with the real world.

However, teaching a robot to navigate a cluttered living room or assemble complex machinery is significantly harder than writing code. The solution? Robot Training Camps—massive, hyper-realistic virtual environments where robots practice for thousands of years in mere hours.

This article explores the explosion of Embodied AI, the mechanics of these virtual training grounds, and why this trend represents the next frontier for technology giants in the US, China, and beyond.

What Is Embodied AI?

Embodied AI refers to artificial intelligence agents that control a physical body—such as a robot arm, drone, or humanoid—and interact directly with the physical environment.

Unlike Large Language Models (LLMs) like GPT-4 or DeepSeek, which operate as “brains in a jar” processing text, Embodied AI systems must process sensory data such as vision, touch, balance, and spatial awareness, then convert that understanding into physical actions.

The long-term goal is a shift from Generative AI (creating content) to Actionable AI (performing real-world tasks).

Read more:

Embodied AI: From Digital to Physical Intelligence

What Are Robot Training Camps and How Does Sim-to-Real Training Work?

Training robots directly in the physical world is slow, expensive, and often dangerous. A robot learning to walk can fall and break; a robot learning manipulation can damage equipment or surroundings.

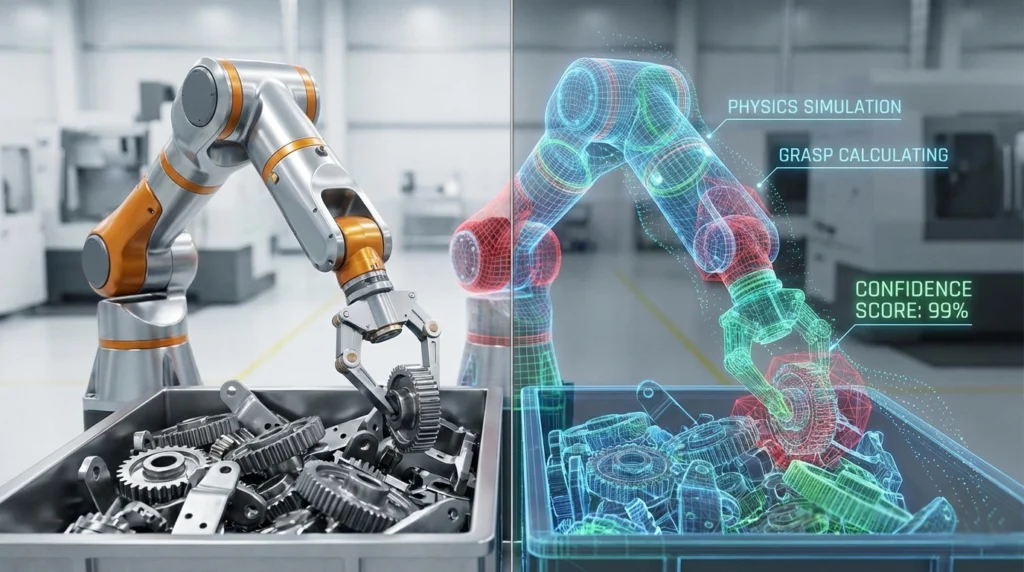

To overcome this, engineers have created massive simulated environments—often built on platforms like NVIDIA Omniverse or proprietary engines developed by Chinese robotics firms. These environments are known as Robot Training Camps.

How It Works

The Digital Twin

A physics-compliant replica of the real world—such as a factory floor, warehouse, or apartment—is created digitally.

Massive Parallelism

Instead of one robot learning at a time, thousands or even millions of virtual robots train simultaneously in the cloud.

Reinforcement Learning

The AI model is rewarded for success (grasping an object) and penalized for failure (dropping or misaligning it), accelerating learning.

Sim-to-Real Transfer

Once the control model is sufficiently trained, it is transferred into a physical robot body.

Key Trend in 2026

The Reality Gap—the mismatch between simulated physics and real-world behavior—has narrowed significantly. AI-driven physics engines can now model friction, soft materials, deformation, and lighting with near-realistic accuracy, making simulation-trained robots far more reliable in the real world.

From Factories to Living Rooms: Real-World Applications

The rise of Embodied AI is driven by two massive markets.

1. The Agile Factory

In manufacturing hubs such as China, rigid automation is becoming obsolete. Traditional industrial robots are programmed for a single repetitive task in a fixed location.

Embodied AI robots can:

-

Identify random objects in bins

-

Adapt to changing assembly lines

-

Collaborate safely with human workers (cobots)

This flexibility enables factories to respond faster to market demand and product variation.

2. The Home Helper

The most ambitious application is the consumer humanoid robot. Companies are racing to deploy robots capable of:

-

Folding laundry, which requires understanding fabric physics

-

Cooking, involving knives, heat, and variable ingredients

-

Elderly care, assisting with mobility, fetching items, and daily tasks

Success in this domain would mark a major shift in how humans interact with machines at home.

Global Embodied AI Hotspots: Who’s Leading the Robotics Revolution?

China: Hardware-Speed Advantage

Chinese firms leverage manufacturing dominance to iterate robot hardware rapidly and at lower cost, while using large-scale factory data to train embodied models.

United States: Foundation Models for Control

US research labs focus on developing general-purpose “robot brains” capable of controlling multiple robot forms, similar to an operating system running on different devices.

Singapore: Urban Testbed

Singapore is emerging as a controlled environment for testing service robots in healthcare, hospitality, and high-density urban spaces.

The Challenges Ahead

Despite rapid progress, Embodied AI still faces major obstacles:

-

Edge Case Problem: Simulations cannot predict every unpredictable real-world scenario (e.g., pets, clutter, or human interference).

-

Energy Efficiency: Advanced AI models consume significant power, limiting robot operation time.

-

Data Scarcity: Unlike text data for LLMs, large-scale datasets of real-world robot actions remain limited.

Additional Real-World Challenges

-

Cost & Scaling: High upfront investment in simulation infrastructure and robotic hardware.

-

Regulation & Liability: Legal responsibility remains unclear when autonomous robots cause harm.

- Trust & Safety: Widespread home adoption requires strong ethical safeguards and public trust.

FAQ:

Why can’t robots be trained only in the real world?

Real-world training is slow, costly, and risky. Simulation allows millions of parallel, safe experiments before deployment.

What is the sim-to-real gap?

It is the difference between simulated behavior and real-world physics. Advances in AI-driven simulation have significantly narrowed this gap.

Is Embodied AI better than traditional industrial robots?

Embodied AI offers adaptability and learning capabilities, while traditional robots excel only in fixed, repetitive tasks.

When will home robots become mainstream?

Limited deployment may begin before 2030, but mass adoption depends on cost, safety, and energy efficiency improvements.

What industries will benefit first?

Manufacturing, logistics, healthcare, and service industries are expected to adopt Embodied AI first.

The year 2026 marks a transition from digital intelligence to physical utility. Robot Training Camps act as the acceleration layer making Embodied AI practical at scale.

For investors and entrepreneurs, value is shifting from Software-as-a-Service (SaaS) toward Robotics-as-a-Service (RaaS)—powered by invisible, infinite training grounds inside simulated worlds.

Content for informational purposes only.